Hydraulic Dampers

The hydraulic damper is made up of a steel cylinder (“body”) inside which a ground, chrome plated (“rod”) slides, reaching theoutside through an oil sealing guide.

End-fittings are applied to the body and rod ends so that they can be fixed.

The elements that identify a hydraulic spring are:

- body diameter;

- rod diameter;

- working stroke;

- end fittings;

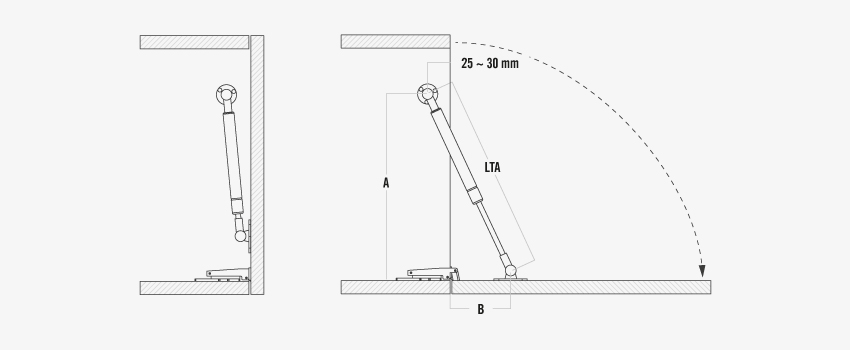

- length of the fully opened spring (LTA), measured from the centre of the body endfitting to the centre of the rod end-fitting;

- degree of braking.

The purpose of installing hydraulic springs on cabinets with downwards opening doors is to slow down the door’s movement. Unlike a gas spring, exercising a pushing action, a damper exercises a braking action during its extension phase, i.e. during door opening, and is on a free run during its compression phase (door closing).

The hydraulic spring must be installed with the rod turned downwards (rod’s end-fitting on the door), in order not to loose braking efficacy.

To avoid loosing out on hydraulic spring efficiency (and prevent oil from leaking out) follow these instructions:

- Avoid any traction being exercised on the door during opening in order not to force the rod exit speed;

- Do not place heavy objects or other heavy items on the door while it is open; should this be necessary, supply the door it with a stop mechanism (chain or bar);

- Do not clean the hydraulic spring with abrasive detergents or other abrasive products;

- Do not hit the spring with blunt instruments.

Strictly necessary cookies

Strictly necessary cookies

Functionality cookies

Functionality cookies

Tracking cookies

Tracking cookies Targeting and advertising cookies

Targeting and advertising cookies